Challenges (and Rewards) of Embracing a Digital Collaboration Platform

Updated 12 February 2026 In the fast-paced, landscape of the oil and gas industry, digital collaboration platforms...

3 min read

Christoffer Sørensen Updated on February 12, 2026

Updated 12 February 2026

Do you remember the shift from storing documents on a shared network drive to collaborating in real time through SharePoint? At the time, it felt revolutionary—multiple people editing the same file, version control, shared access.

But despite its early impact, SharePoint still acts as a silo that limits efficiency, consistency and cross-disciplinary collaboration.

This article is written for drilling and well teams seeking better ways to manage operational data—and for those evaluating what a transition from traditional systems like SharePoint to an integrated software platform could mean for daily workflows and overall performance.

SharePoint was designed primarily for document storage and management, not cross-functional operational collaboration. In drilling and well operations, this results in fragmented information.

Common challenges include:

Department-specific SharePoint sites with different structures and naming conventions

Limited real-time data visibility across drilling, completions, subsurface, logistics and vendors

Information lag, requiring manual updates, screenshots, exports and email circulation

No unified operational context, making it difficult to see how documents relate to current well status or execution workflows

Over time, SharePoint becomes a passive repository, not an active operational tool. In a domain as dynamic as drilling and wells, that gap directly impacts NPT, safety and decision quality.

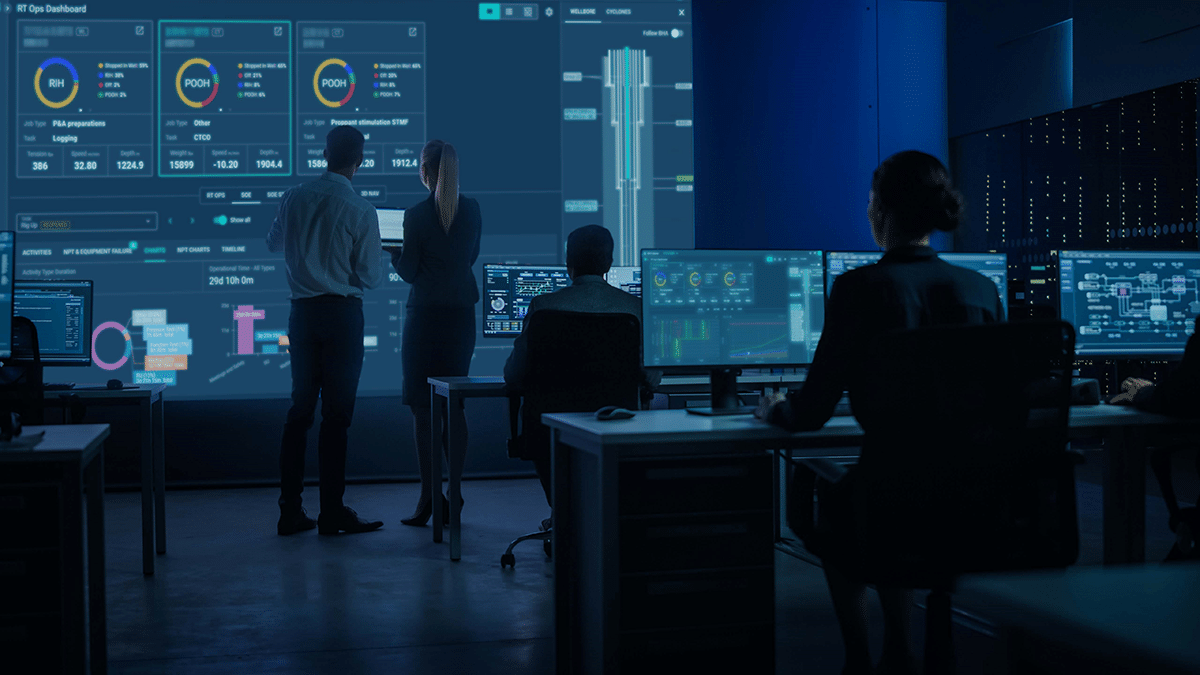

An integrated platform provides a unified digital environment where data, workflows, and applications from across drilling and wells come together.

Unlike isolated applications, these platforms emphasize:

Interoperability between tools and databases

Real-time data accessibility across stakeholders

Contextual workflows that connect planning, execution and reporting

Reduced manual handling of data and documents

A single source of operational truth

Put simply, an integrated platform removes friction, minimizes administrative workload and strengthens data-driven decision-making.

Read more: What is an open data platform in drilling and well operations?

For drilling and well operations managers, moving away from SharePoint is no longer a convenience—it’s a strategic requirement.

Integrated platforms address several real-world challenges:

Unified access to plans, risks, real-time data, operations history and vendor inputs ensures everyone works from accurate, consistent information.

Automated workflows remove repetitive manual tasks, reduce administrative burden and help cut NPT.

When wells behave unexpectedly, or when field conditions change, integrated systems support rapid, informed response.

Read more: Quantifying the Value of IDEX: Real-World Impact Across Leading Operators

Routine processes—data sharing, updates, handovers, quality checks—can be automated, reducing both effort and human error.

Live data availability allows teams to identify anomalies and react quickly.

For instance - If a problem arises such as stuck BHA, the software immediately flags the anomaly and alerts the onshore team. Engineers and managers on duty access the real-time data via the real time dashboard and can quickly analyze the data trends leading up to the alert, confirming the risk of a stuck tool.

Using the software’s decision support tools, the team simulates various response scenarios and decides to attempt cycling free the tool from the tight spot. The software platform facilitates rapid communication and coordination with the onshore and offshore team in the implement the procedural changes.

The corrective action frees the tool within minutes. Continuous monitoring confirms that the weights and other parameters return to normal levels, averting a potential fish. The swift, data-driven response prevents what could have been hours or even days of downtime, not to mention the avoidance of HSE hazards.

Cross-functional alignment—engineering, logistics, subsurface, service companies—reduces delays, miscommunication and planning conflicts.

Built-in communication tools ensure faster, more accurate information flow than document-based updates ever could.

Read more: One Digital Well, how do we get there?

Integration brings together all digital tools used across drilling and well operations into a single, interactive architecture.

It typically includes:

APIs enabling communication between systems

Mapping of existing data flows to identify integration points

Security implementation (access control, audit trails, encryption)

Testing and alignment with operational workflows

A successful integration respects existing infrastructure while eliminating inefficiencies.

For drilling and well operations managers, the shift from siloed systems like SharePoint to integrated software platforms is essential for modern performance.

With integrated platforms, you can:

Break down data silos

Improve efficiency and reduce NPT

Support better real-time decision-making

Strengthen cross-team collaboration

Prepare for future technologies and data-intensive workflows

As the industry continues to evolve, embracing integrated platforms isn’t just smart, it’s necessary for maintaining competitive advantage and operational excellence.

Equip your teams for today’s challenges and tomorrow’s opportunities.

SharePoint was built for document storage, not end-to-end operational collaboration. Different teams often manage their own sites and structures, creating fragmented information, limited real-time visibility and a lack of unified operational context, which can directly affect NPT and decision quality.

An integrated software platform is a unified digital environment that connects data, workflows and applications across drilling and well operations. It emphasizes interoperability, real-time data access, contextual workflows and a single source of operational truth.

They automate routine workflows, provide real-time access to operational data and support faster, data-driven responses to problems such as stuck BHA events. This reduces manual effort, minimizes errors and shortens downtime.

By bringing data from engineering, subsurface, logistics, service companies and other stakeholders into one platform, teams can align plans, anticipate issues and communicate through built-in tools instead of fragmented document-based updates and email chains.

Integration usually includes mapping current data flows, identifying key integration points, using APIs to connect systems, implementing security controls and testing workflows to ensure the platform fits existing infrastructure while eliminating inefficiencies.

Updated 12 February 2026 In the fast-paced, landscape of the oil and gas industry, digital collaboration platforms...

Updated 12 February 2026 In today’s upstream environment, success in drilling, completion, well intervention, and...

Updated 12 February 2026 Wondering how to optimize your approach to the huge amount of data and actors in drilling...