AI – How Can It Help Planning and Executing Well Intervention Jobs?

Updated 12 February 2026 There’s no doubt that there is a real buzz about AI, and have been for some time. Which...

Updated 12 February 2026

The idea of a fully digital well, where data flows seamlessly across planning, execution and post-job learning, has long been a vision for the oil and gas industry. Yet the gap between ambition and reality remains significant. As early as 2016, McKinsey Digital highlighted oil and gas as one of the least digitized industries in the global economy. Nearly a decade later, progress is visible, but the overall digital maturity of the sector still trails other industries by a wide margin.

The challenges are not new: inconsistent operational performance, organizational misalignment, fragmented data ecosystems, and low readiness for digital transformation. But the opportunities are greater than ever. New technologies, modern collaboration platforms and AI-driven analytics are reshaping what is possible, if companies are ready to adopt them.

This article outlines the key challenges, industry insights and practical pathways toward achieving the vision of One Digital Well.

In a 2024 interview, Molly Smith, VP of Drilling and Completions at Murphy Oil, summarized the industry’s path forward:

“I think there are three things the industry needs to focus on with data;

First, standardization needs to improve so that we can reduce the time we spend engineering data and increase the time we spend analyzing data.

Second, we need to invest in innovating machine learning and artificial intelligence methods so that they can fit with more industry-centric datasets and workflows.

And third, we must improve the efficacy of our data-modeling methods so that they can give us a more comprehensive understanding of our operations.”

This perspective captures three of the largest barriers to digital adoption:

Poor data standardization

Limited support for oilfield-specific AI/ML workflows

Fragmented data models that weaken operational understanding

At Stimline Digital, we share this view. Tools like the IDEX Collaboration Platform, already used by Shell to standardize global well operations, give engineering teams more time to analyze, optimize and deliver higher performance rather than manipulating data manually.

Read more: Thank Goodness We Decided That Openness Is The Way Forward

Market uncertainty continues to pressure operators to become more efficient. Digitalization and automation are no longer “innovation projects”, they are fundamental levers of competitiveness.

Climbing the digitalization ladder offers clear advantages:

Lower cost per well

Faster diagnostics

Higher operational consistency

Stronger decision-making driven by real-time data

However, McKinsey’s research shows that 70% of digitalization initiatives never move beyond the pilot phase. The issue is rarely technology. The barriers are human, organizational and structural.

Read more: New methods of post job analysis (traditional vs new)

Surprisingly, the issue isn't usually the technology itself. Many pilot projects succeed, meeting or surpassing their technical goals. The real issue lies in three significant cultural and organizational barriers.

1. Unclear or Missing Value

Digital initiatives fail when they do not address the true operational bottlenecks. If a use case cannot demonstrate measurable bottom-line impact, scaling becomes difficult—no matter how innovative the technology is.

2. Workforce Resistance and Skill Gaps

Employees are asked to adopt new tools, change familiar workflows and develop new competencies. Without clear incentives and strong operational support, resistance is inevitable.

3. Treating Digitalization as a “Project,” Not a System

Many companies run isolated pilots in parallel with legacy systems. When the pilot ends, workflows revert.

For digitalization to scale sustainably, it must be integrated into:

Organizational structures

Operational timelines

Existing software landscapes

Standard planning and execution processes

The IDEX Collaboration Platform is designed specifically to overcome these barriers. It is:

Open – integrating easily with third-party or in-house systems

Flexible – supporting real-world workflows across planning, execution and reporting

Scalable – built for enterprise-wide adoption, not isolated pilots

Contextual – aligning data, decisions and accountability across the well lifecycle

IDEX provides the transparency and consistency needed to move from fragmented digital efforts to a unified, end-to-end operational ecosystem, the foundation of One Digital Well.

The journey toward a fully digital well is far from complete, but the industry is moving in the right direction. With the right tools and frameworks, like the IDEX Collaboration Platform, operators can unlock:

Higher productivity

More meaningful use of data

Stronger collaboration between teams

Faster learning loops and continuous improvement

Digitalization is no longer a vision of the future; it is a requirement for operational excellence today. Those who embrace it will shape the next era of well operations.

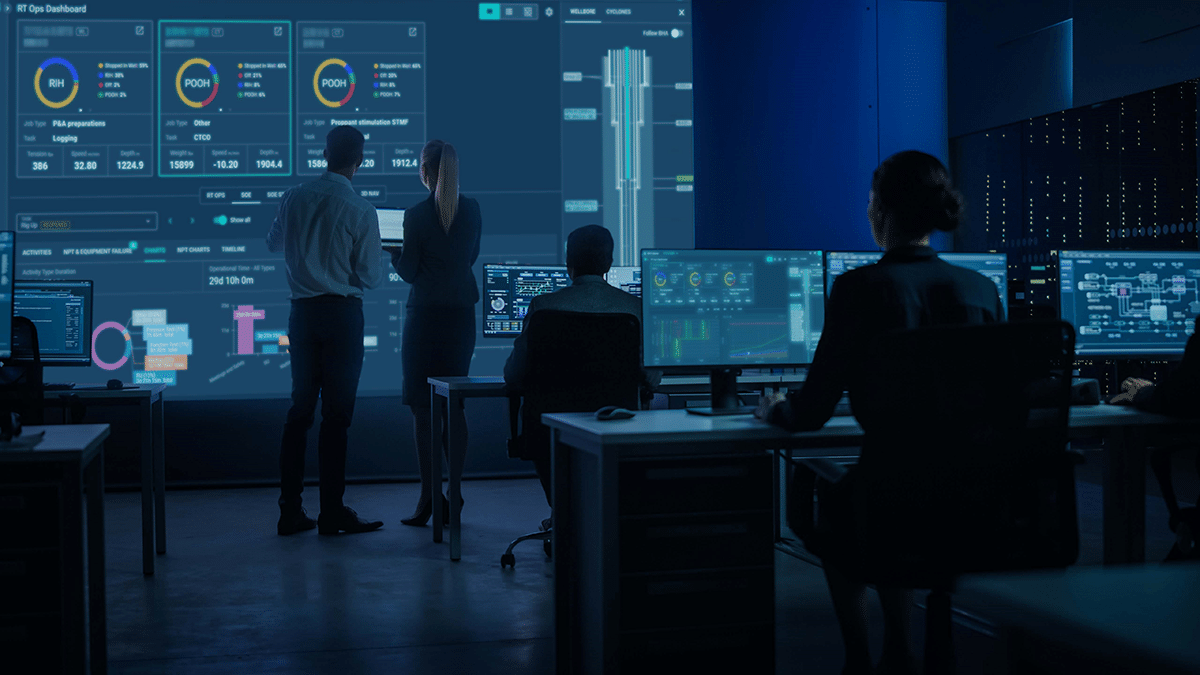

A Digital Well is an operational environment where data flows seamlessly across planning, execution and post-job analysis. It integrates real-time information, standardized workflows and collaborative tools so that engineering teams can make faster, more accurate decisions throughout the well lifecycle.

Despite progress, the sector still faces inconsistent performance, organizational misalignment, fragmented data, and low digital readiness. McKinsey research shows that 70% of digital initiatives stall at the pilot stage due to human, structural and cultural barriers, not because the technology fails.

The article highlights three major barriers: poor data standardization, limited AI/ML support tailored to oilfield workflows, and fragmented data models that prevent a full operational understanding. These issues force engineers to spend more time engineering data instead of analyzing it.

Projects often fail to demonstrate clear value, struggle with workforce resistance, or remain isolated pilots that never integrate with core operational systems. Without alignment to organizational structures, timelines and existing software, digitalization cannot grow beyond a small experiment.

IDEX is designed to overcome typical digitalization barriers. It integrates with third-party systems, supports real operational workflows, scales across the enterprise and aligns data with decisions. This creates a unified ecosystem that enables higher productivity, better collaboration and faster learning across well operations.

Updated 12 February 2026 There’s no doubt that there is a real buzz about AI, and have been for some time. Which...

Updated 12 February 2026 Digitalization is an ongoing trend, affecting all industries including the energy industry....

Updated 12 February 2026 In the fast-paced, landscape of the oil and gas industry, digital collaboration platforms...